Model NO.: HQ-LK1.0

Trademark: HAIQI

Origin: Shangqiu, China

HS Code: 8416209090

1.Haiqi Company introduction We are Shangqiu Haiqi Machinery Equipment, Co., Ltd. Which is specialized in the biomass burner, biomass MSW gasifier and the biomass MSW gasification power generation & gas supply system. The biomass burner is very environmental and energy saving. 2.biomass burner application fieldThe biomass burner can apply to steam boiler, hot water boiler, aluminum melting furnace, industrial furnace, incinerator, drying equipments, food drying equipments, spray drying equipments, industrial annealing furnace, asphalt heating equipments, press casting machine, ect.

2.biomass burner application fieldThe biomass burner can apply to steam boiler, hot water boiler, aluminum melting furnace, industrial furnace, incinerator, drying equipments, food drying equipments, spray drying equipments, industrial annealing furnace, asphalt heating equipments, press casting machine, ect.

3.feedstock of biomass burner

Types of raw materials: suitable for wood pellet, palm shell pellet, wood chips, plam shell, olive shell, coffee shell, strawpellet, biomass pellet......

Raw material requirements: diameter 6-10mm

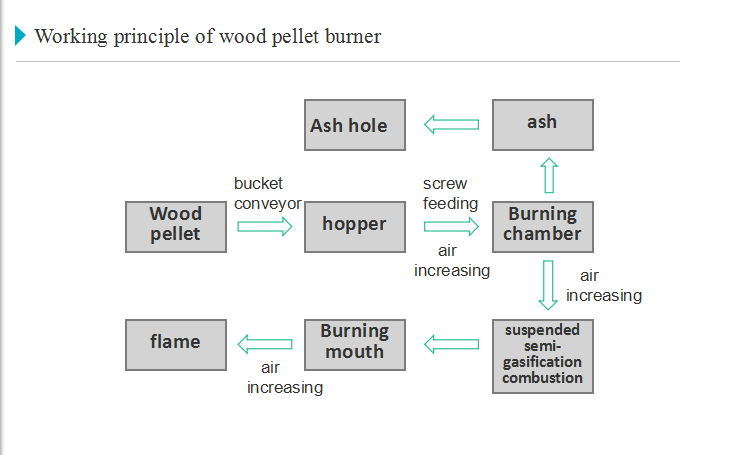

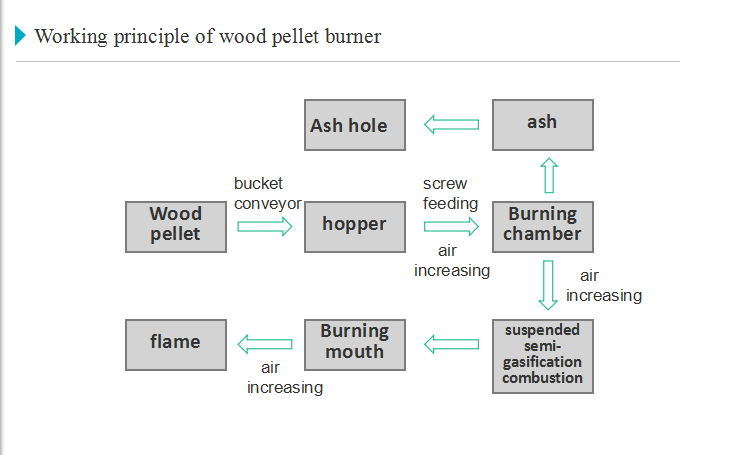

4. Running process of biomass burner

1.the wood pellet is conveyed into the hopper by screw conveyor.

2. there is screw propeller which is used for propelling wood pellet into the burner furnace, also there is a blower blow the pellet into the burner furnace.

3.the burner furnace from the outside, the first layer is steel , then water jacket,boiler steel ,castable refractory , fire bricks. the water jacket is used for cooling the burner furnace and lengthen the service life , the temperature of the water jacket is 60-70 degree, the temperature in the furnace is about 800-900degree. the water jacket could connect with the cold water tank, it's function just like a economizer.

3.there is view hole and check hole on the burner furnace to check the combustion condition in the burner furnace.

4. there is big bottom fan blow the wind from the bottom of the burner, the wind enter into the furnace from the side edge, make the wind take along wood pellet rotate and fly, the wood pellet expose in the air in 360 degree completely, to get sufficient oxygen, burn sufficiently, increase heat efficiency.

5. ignite, put some wood chips in the furnace, there is automatic diesel ignitor which used for igniting,or just put some wood chips with diesel then fire it.

6.ash discharge ,there are two ash discharge hole set on and under the grate, just need clean it every 5-7 days, because of the sufficient combustion,only little ash produce.

7. there is a blower set in the flame outlet, it is used for lengthen the flame , by control the wood pellet feeding speed and blower speed , burner could switch soft fire-medium fire-big fire, the flame temperature is about 1100-1300 degree, the length of the flame is about 3-6m.

5.Feature of biomass burner:

1. Easy to operate and use, the machine adopts PLC control panel which can realize small fire-middle fire-big fire. Customize electrical components according to customers requirements, there are domestic components and imported components available, we will offer free replace parts within one year because of quality problem.

2. The combustion furnace adopts 3-layer thermal insulation, the inner furnace adopts high aluminum refractory ,anti-souring and high temperature resistance. Outside of the furnace, it uses water cooling system, make sure the furnace have long usage life, and operation more stable.

3. Pyrolysis and gasification through negative pressure, secondary combustion,smoke treatment system, eliminate the secondary pollution completely, up to European emission standard.

4. The biomass burner adopts ultra-low nitrogen combustion technology, multiple air increasing, high temperature pyrolysis, semi-gasification suspension combustion,use heat convection and radiation at the same time, combustion last for more than 2 seconds, high-speed combustion and no dead corner.

5. High thermal conversion efficiency, heat efficiency can reach 90%-95% generally, stable continuous operation, easy to operate and maintenance.

6. Well sealing measures and negative pressure furnace, ensure no gas leakage.

6.Available capacity of biomass burner

| Model |

Main burner size(L*W*H)mm |

wood pellet

consumption(kg/h) |

caloric value

(kcal) |

weight

(Ton) |

|

|

|

| HQ-LK0.5T |

1900*1200*2050 |

70 |

300000 |

1 |

| HQ-LK1.0T |

2500*1914*2636 |

155 |

600000 |

1.5 |

| HQ-LK1.5T |

2500*1914*2636 |

230 |

900000 |

2 |

| HQ-LK2.0T |

3150*2300*2923 |

310 |

1200000 |

2.5 |

| HQ-LK3.0T |

3150*2400*2923 |

460 |

1800000 |

3 |

| HQ-LK4.0T |

3150*2400*2923 |

600 |

2400000 |

3.5 |

| HQ-LK5.0T |

3829*2982*3131 |

750 |

3000000 |

4.3 |

| HQ-LK6.0T |

3829*2982*3131 |

1000 |

3600000 |

5 |

| HQ-LK7.0T |

3832*2990*3200 |

1100 |

4200000 |

6 |

| HQ-LK8.0T |

3840*3000*3300 |

1200 |

4800000 |

7.2 |

| HQ-LK10T |

3850*3100*3400 |

1500 |

6000000 |

9.5 |

7.installation site photo of biomass burner